What

happened? The change

point analysis will tell you

by

Vincent

Béchard, ing., M.Sc.A.

Martin

Carignan, M. Sc., MBA

Différence,

consulting in

statistics

www.difference-gcs.com

Relevant questions, imperfect tools

The questions we try to answer when we look at historical process data

or a key performance indicator (KPI) are: did a change occur? Did more

than one change occur? When? What was their amplitude? How confident

are we it is a “real” change? In fact, what we are

looking for is a change (or several changes) in the mean of a process.

Typically, some people will look at their historical data on a run

chart and subjectively try to identify trends. This approach often

leads to identifying many trends that are not

‘real’. For example, some people will consider

seeing three points in a row increasing as a signal of a trend up while

we know that this situation could happen quite often just by chance.

Others will use a statistical tool, like the ImR, EWMA and CUSUM

control charts. Unfortunately, control charts were not invented to

identify changes in historical data but rather to monitor a process and

allow separating between normal and assignable causes variation. Using

a control chart with the objective of identifying changes in historical

data is better than just using a run chart but it is not the most

effective tool.

The Change Point Analysis

An efficient tool to identify changes in historical data is change

point analysis (CPA). CPA is a procedure aiming at detecting any change

in the mean of a process. It is intended to be applied on a

“long” period of historical data.

The CPA procedure is a mixture of two powerful tools: CUSUM and

bootstrapping. It is an iterative algorithm that decomposes the dataset

into stable sub-periods having different means. For each change in mean

detected in the process data, CPA returns a p-value: the probability of

being wrong if we conclude that the identified shift is

‘real’.

An example

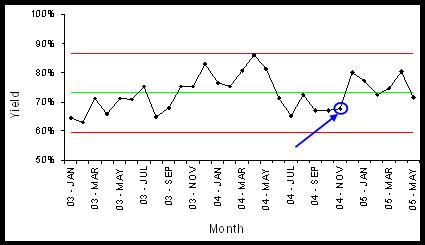

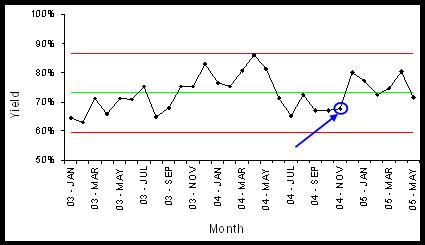

Let's consider the historical yield of a process (see Figure 1). The

data have been collected between January 2003 and May 2005. Classical

questions are: “What happened during this period? Did the

yield change? Did we experience good and bad periods?” Using

a conventional ImR chart, with control limits at ± 3, the

Western Electric rules would detect a special cause on November 2004 (4

out of 5 points in zone B or beyond). Even with this information, is it

really clear when the yield really changed? By how much? With what

confidence?

Figure 1: Yield data on

an ImR chart

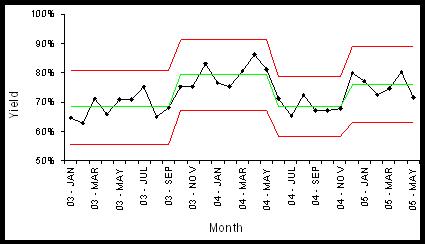

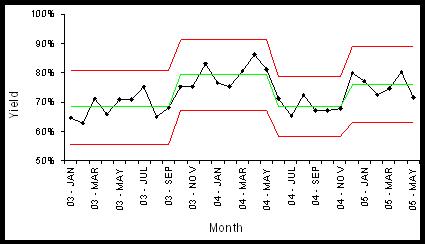

Using

the CPA algorithm, we found out that 3 changes occurred (see Table 1).

The results are 4 different stable periods, as illustrated below (see

Figure 2).

Figure

2: Yield data after change point analysis

Table

1 - Changes in process mean

|

Change point

|

p-value

|

Shift

meanafter

– meanbefore

|

|

1

|

0.036

|

+ 0.109

|

|

2

|

0.021

|

- 0.107

|

|

3

|

0.023

|

+ 0.076

|

You

can surely notice that the changes in yield are identified very clearly

with CPA compared to the ImR chart. We also have a good idea when the

change in mean did take place and the magnitude of the change.

Conclusion

There is no doubt about the usefulness of investigating historical data

of a process or performance indicator. The change point analysis (CPA)

is a very powerful retrospective analysis tool. It provides

easy-to-interpret results leading to better decision making.

If you have questions or

comments, you can reach Vincent

Béchard and Martin Carignan at info@difference-gcs.com,

or by consulting their web site (www.difference-gcs.com).